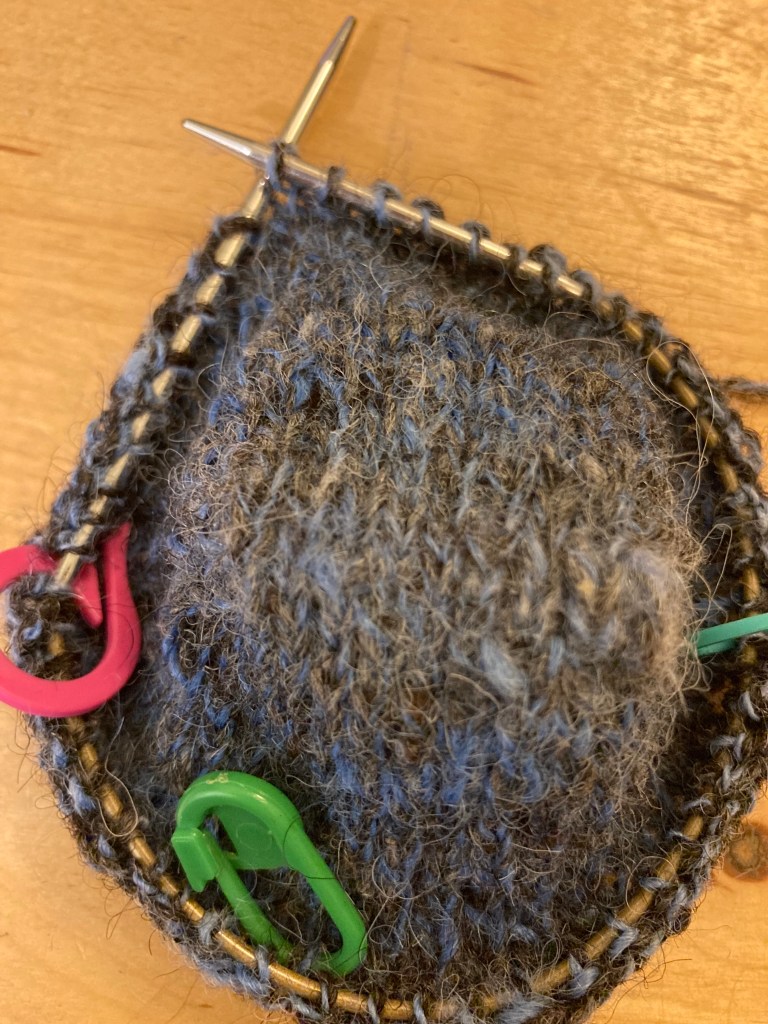

Fresh off the needles today, one pair of socks in handspun alpaca and wool. This is the first pair I’ve made from the toe up.

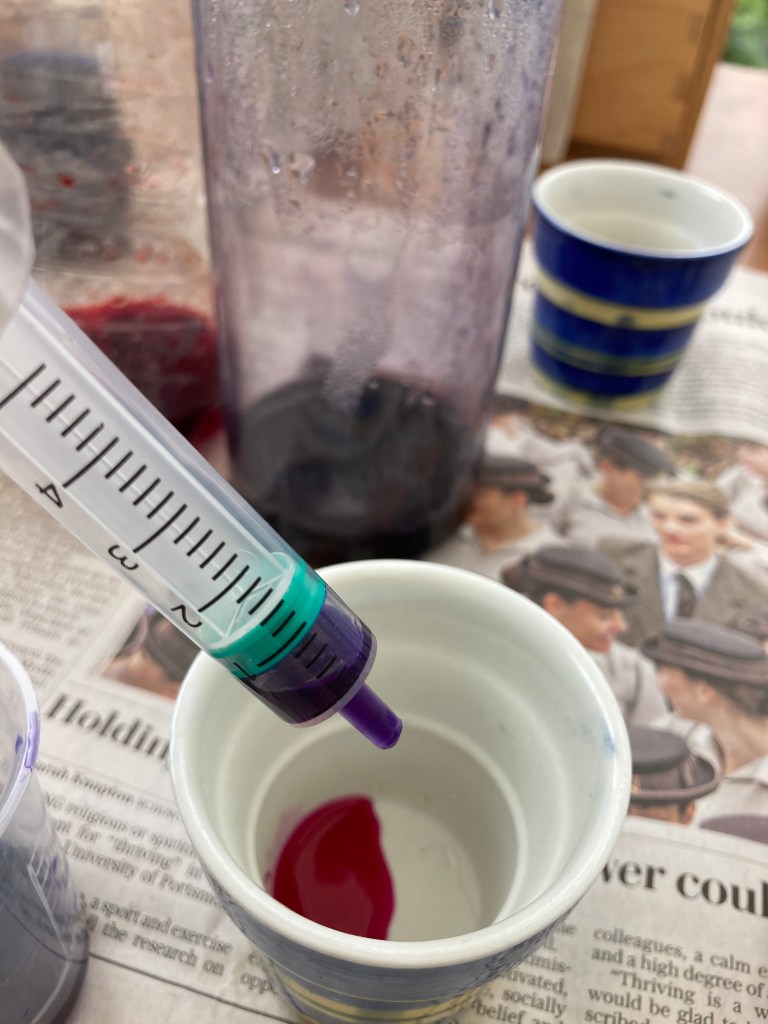

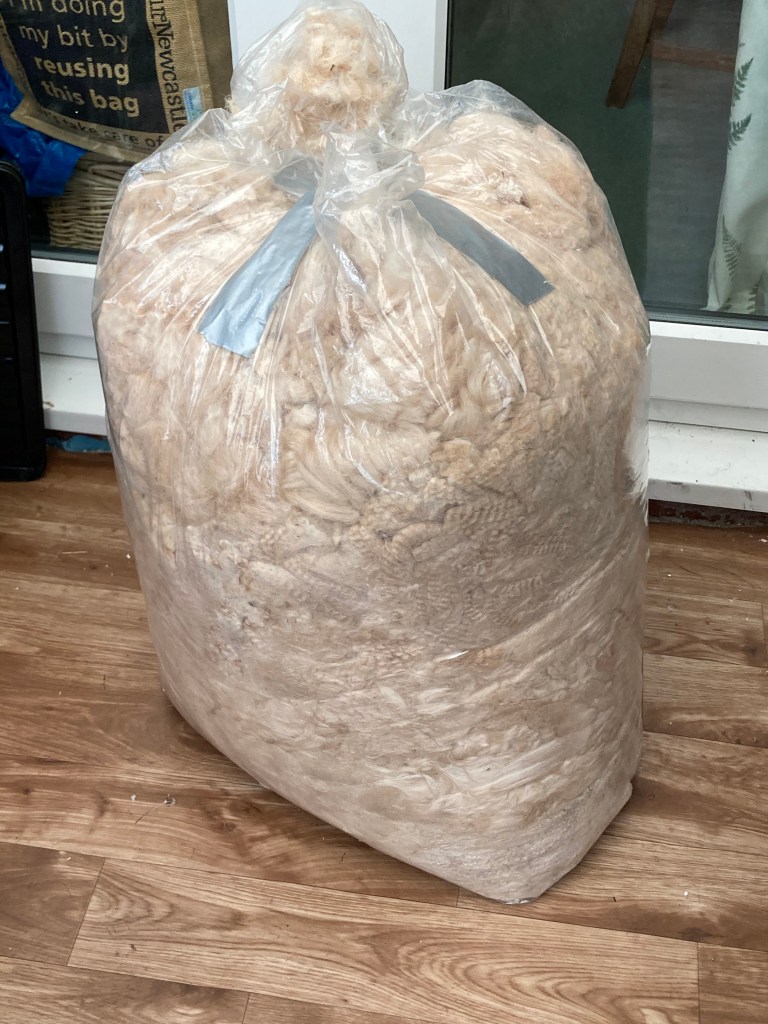

This pair began its journey last summer with one of my first dyeing experiments. I gradient dyed a braid of alpaca in shades of blue, navy, purple, pink and red. You can read about where my alpaca fibre came from here

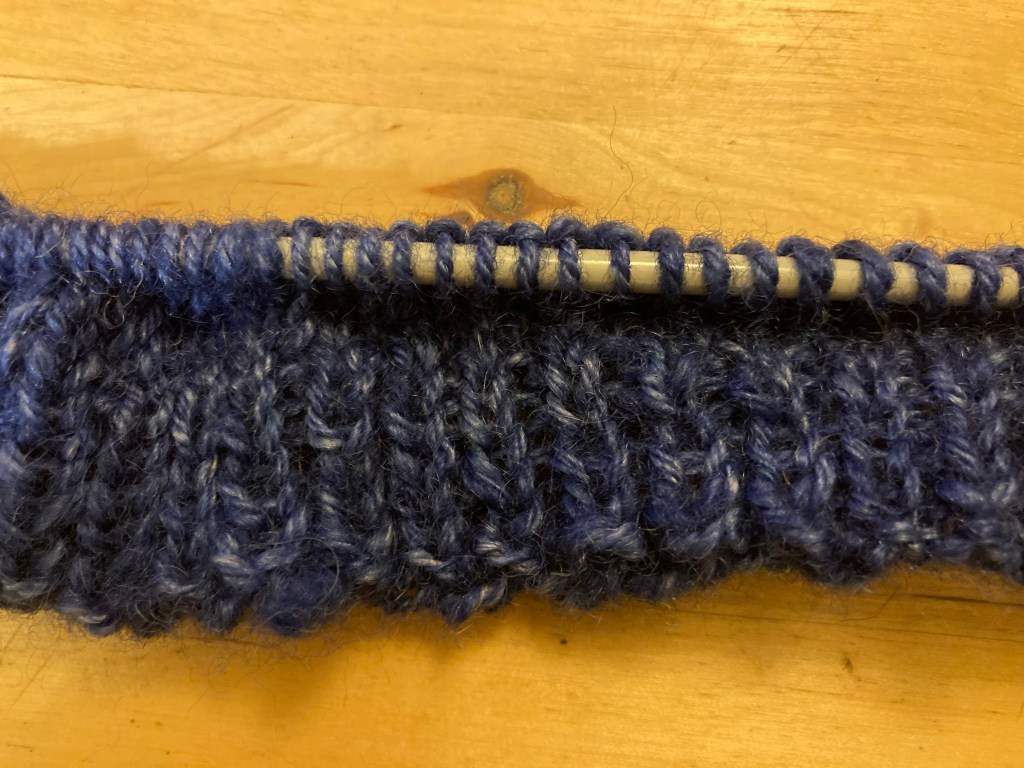

I spun the yarn and plied it with black zwartbles sheeps wool.

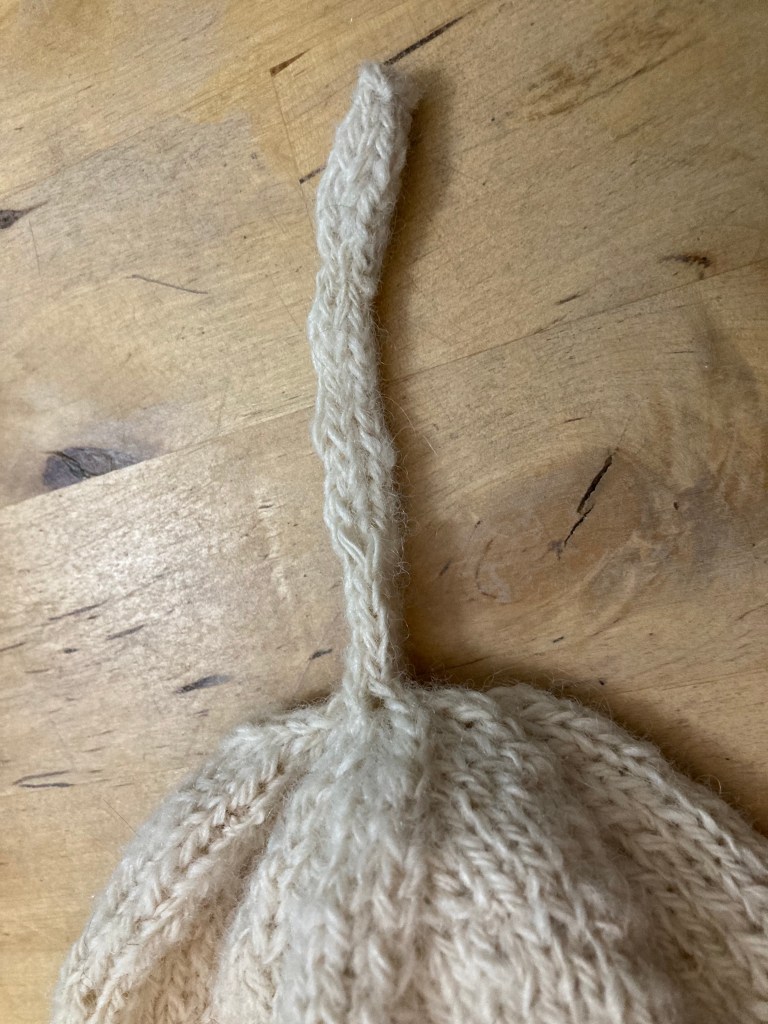

As I wasn’t sure about the yardage I’d need I decided on a toe-up pattern. If I’d knitted a top down sock it would have been a catastrophe if I’d run out of yarn before I reached the toe. On the other hand, working from the toe up could end up ankle or knee length without it really mattering! This pattern is Route 45’s Basic toe-up socks. It gives lots of options for needle size, and works whether you prefer DPNs small circular or magic loop. There is also a measuring guide so you can create perfectly fitted sock.

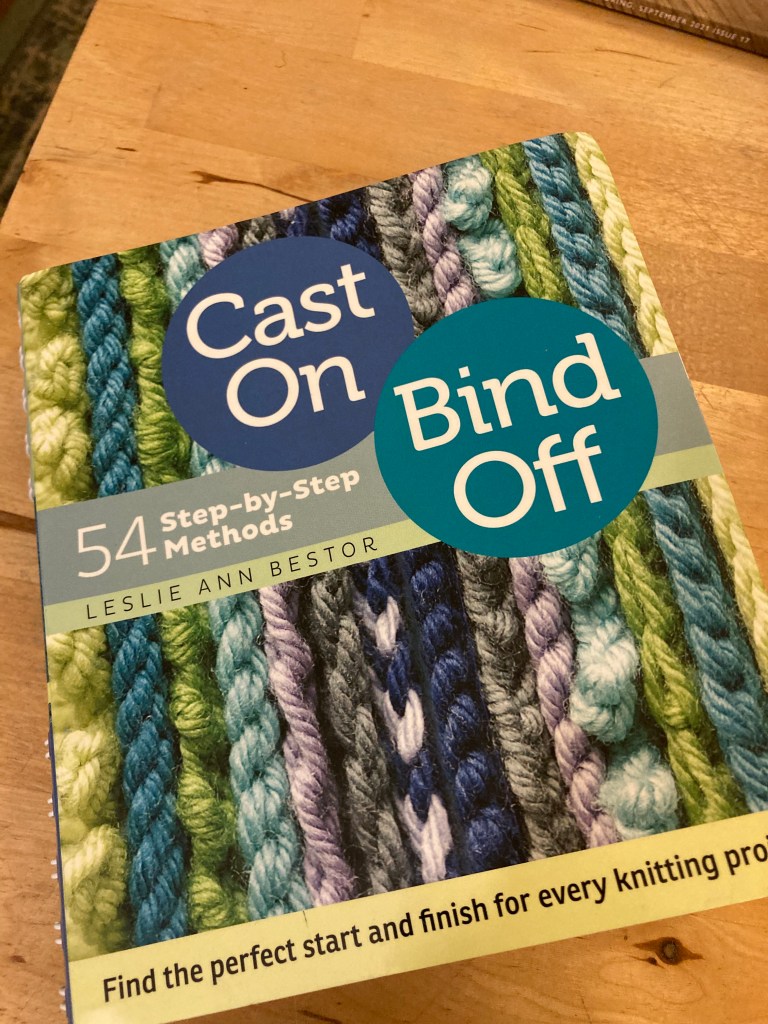

The other resource I used was this book I got for Christmas.

Who knew there were so many cast on/off methods? Several ways of starting off sock toes are included. The pattern uses the Turkish cast on, which was a first for me.

The book came in again for the cast off on the cuff – I used Jeny’s Surprisingly Stretchy Bind off, which is a pretty good description….very stretchy.

I’ve really enjoyed knitting these. I love the the way the colours work, Both the gradient and the way that plying with black tones down the colour and gives a tweedy effect when knitted up. The gradients don’t match but I can live with that.

Toe up construction has been a bit of a game changer. I always disliked picking up stitches on the gusset with top down socks and there’s none of that here. I don’t think I’ll be going back to top downs after this.

And as for worrying that I might run out of yarn….well there’s just about enough for another pair!